Velocity vs. Accuracy: Identifying the Perfect Equilibrium in Cutting

In the realm of production cutting and manufacturing, the ongoing dialogue of speed versus precision is a crucial consideration for companies aiming to improve their operations. As tech evolves, the equipment available for cutting materials have diversified, offering alternatives like laser and waterjet cutting solutions that address varying needs. Each cutting method has its own set of benefits and drawbacks, making it crucial for fabricators to find the ideal balance between rapid throughput and the delicate accuracy required for premium results.

Fabbers frequently face the hurdle of meeting tight deadlines while also ensuring that their products comply with rigorous quality standards. The choice between velocity and precision can dramatically impact manufacturing efficiency, costs, and ultimately customer satisfaction. Understanding laser and waterjet cutting service of different cutting techniques, such as laser and water jet, is necessary for making wise decisions that align with the particular demands of a project. In this article, we will explore these cutting processes and how businesses can effectively navigate the complex dynamics of speed and accuracy in their manufacturing operations.

Comprehending Laser Engraving

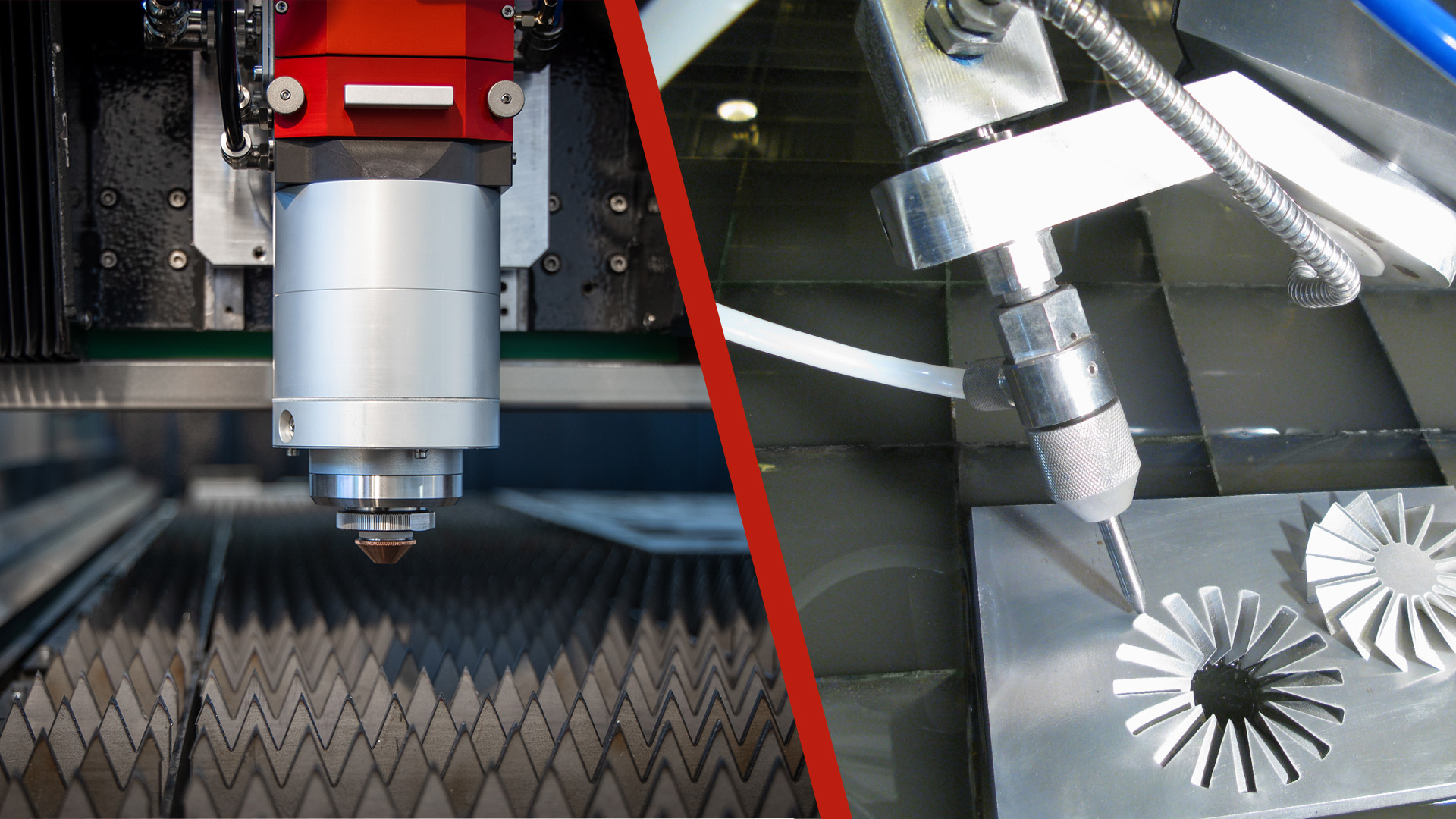

Laser cutting is a highly exact and effective method used in production industry. This technique utilizes a concentrated beam of light to melt material, creating clean and detailed cuts. The accuracy of laser cutting makes it suitable for a variety of materials, including metals, plastics, and timber, allowing for complex designs that would be hard or not feasible to achieve with traditional cutting methods.

One of the key benefits of laser cutting is its quickness. The process can be mechanized, allowing for fast production while ensuring elevated quality. As the beam travels swiftly across the material, it creates minimal waste, which contributes to cost savings and efficiency in the manufacturing process. Additionally, the contactless nature of laser cutting means there is less wear on tools, which lowers maintenance costs and downtime.

Moreover, laser engraving is highly versatile. Different types of lasers, such as CO2 and fiber lasers, are used for various applications, depending on the particular material and thickness being cut. This adaptability makes laser cutting a favored choice in multiple industries, from automotive to aviation, where accuracy and rapidity are crucial for competitive manufacturing.

Investigating Water-Jet Cutting Process

Water Jet cutting is a adaptable and powerful method used in industrial processes. It utilizes a high-pressure stream of water, often mixed with abrasive materials, to sever through a variety of materials including metal, plastic, glass, and rocks. One of the most significant advantages of water-jets cutting is its capability to process heavy materials while producing clean cuts without the heat-induced alterations that other cutting methods might generate. This feature makes it suitable for purposes where accuracy and structural integrity are crucial.

The versatility of water jet cutting allows it to be used in various industries, from space exploration to fashion. The ability to create intricate designs and form intricate shapes adds to its charm, enabling designers to push the frontiers of design. Since waterjet cutting does not involve any thermal processes, it is particularly advantageous when working with temperature-sensitive materials that might warp or alter characteristics due to high temperatures.

Additionally, the environmental impact of waterjet cutting is comparatively low compared to other machining techniques. The method creates minimal waste, especially since it can typically reuse the abrasive materials. Additionally, water jet cutting uses water as its main cutting tool, making it a cleaner alternative. This congruence with eco-friendliness is becoming progressively important in modern manufacturing landscape, where companies are looking for methods to reduce their ecological footprint while maintaining high levels of effectiveness and precision.

Reaching Ideal Balance

In the competitive arena of manufacturing cutting, the quest for an maximal balance between velocity and precision is paramount. Each production operation, whether employing light-based or water jet machining services, has unique attributes that can influence the overall efficiency and standard of production. Firms must take into account the unique requirements of their assignments, as some applications may emphasize quick material extraction, while others require detailed accuracy to achieve tight tolerances.

To attain this equilibrium, manufacturers often examine advanced technologies and equipment improvements that cater to both factors. For example, adopting automation and computer numerical control (CNC) can considerably enhance the velocity of operations without sacrificing accuracy. Furthermore, regular servicing and precision calibration of cutting machines ensure reliable output, eventually leading to improved turnaround times and top-notch results that meet stringent market requirements.

In addition, ongoing evaluation of materials and cutting methods is vital in perfecting the equilibrium between velocity and accuracy. Multiple materials respond distinctly to cutting techniques, and grasping this interaction facilitates better judgments. By experimenting with different combinations of cutting speed, feed speeds, and machine settings, organizations can refine their operations, resulting in enhanced efficiency and lessened loss, guaranteeing they keep relevant in the constantly changing manufacturing sector.